CNC Contour Cutting

Automated foam cutting CNC technology in combination with various CAD technologies has resulted in numerous advantages for foam fabrication including: improved dimensional accuracy, increased cutting speed, consistency of contoured parts, reduced foam dust, improved material yield, and improved operator safety.

redundantly equipped plants ensure cnc capacity

With 14 total CNC contour machines across the network of five plants, our CNC capability is among our most powerful capabilities. The accuracy, efficiency, and creativity provided by these machines makes them a pillar for any fabrication process.

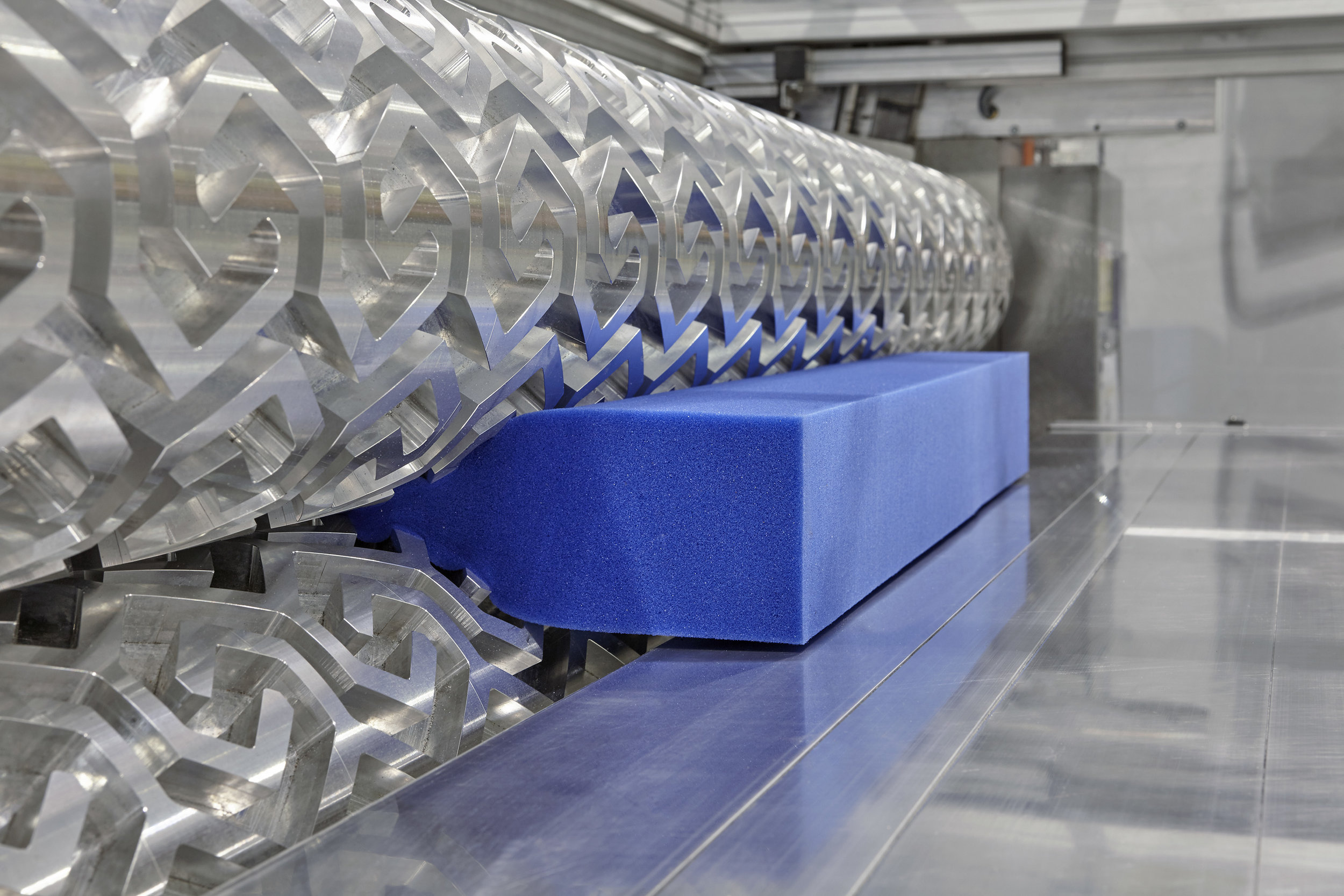

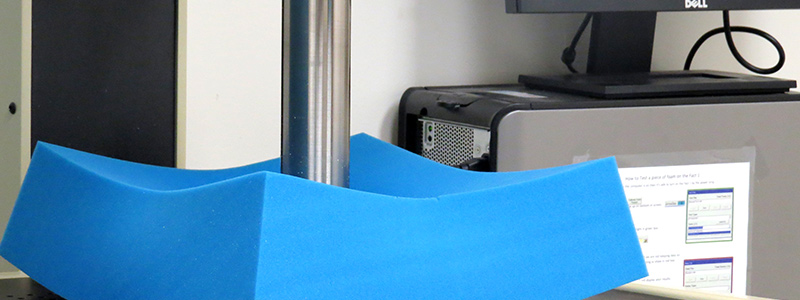

HORIZONTAL CNC

One of the most dynamic machines available, the Horizontal CNC machines offer maximum productivity combined with the highest quality standards. Equipped with a rotating material table, these machines can cut across two dimensional planes, creating the potential for near 3D foam parts. With 8 of these in the Foamcraft network, this capability is available at every plant.

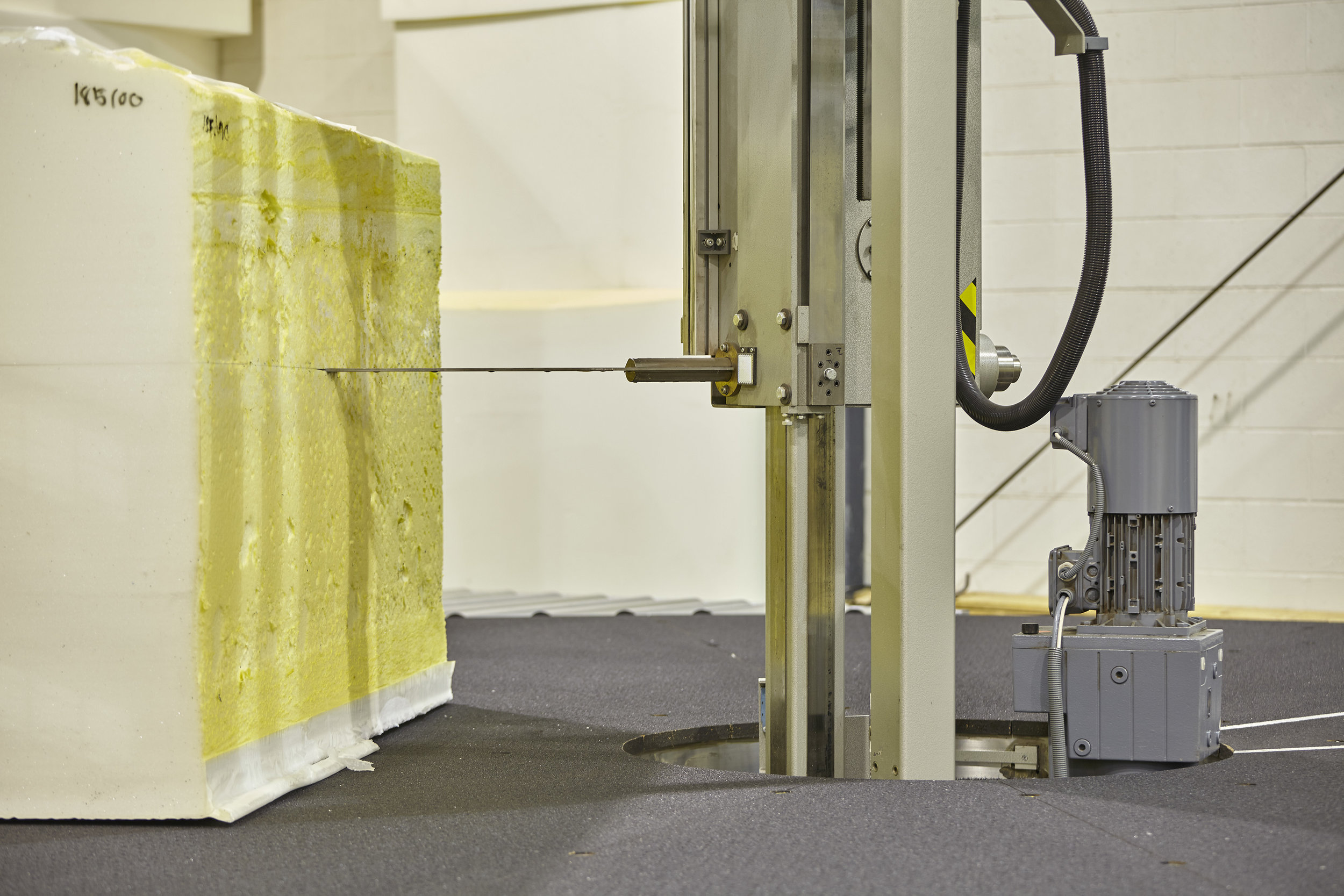

VERTICAL CNC

Able to cut efficiently and with a high level of accuracy, our Vertical CNC machines are the work horses of the company. The CAD integration optimizes cutting lines as an automated cutting process and provides nesting capabilities to reduce foam scrap and optimize customer costs. With five in the company, and one on the way, they are viewed as a necessity for efficient production.

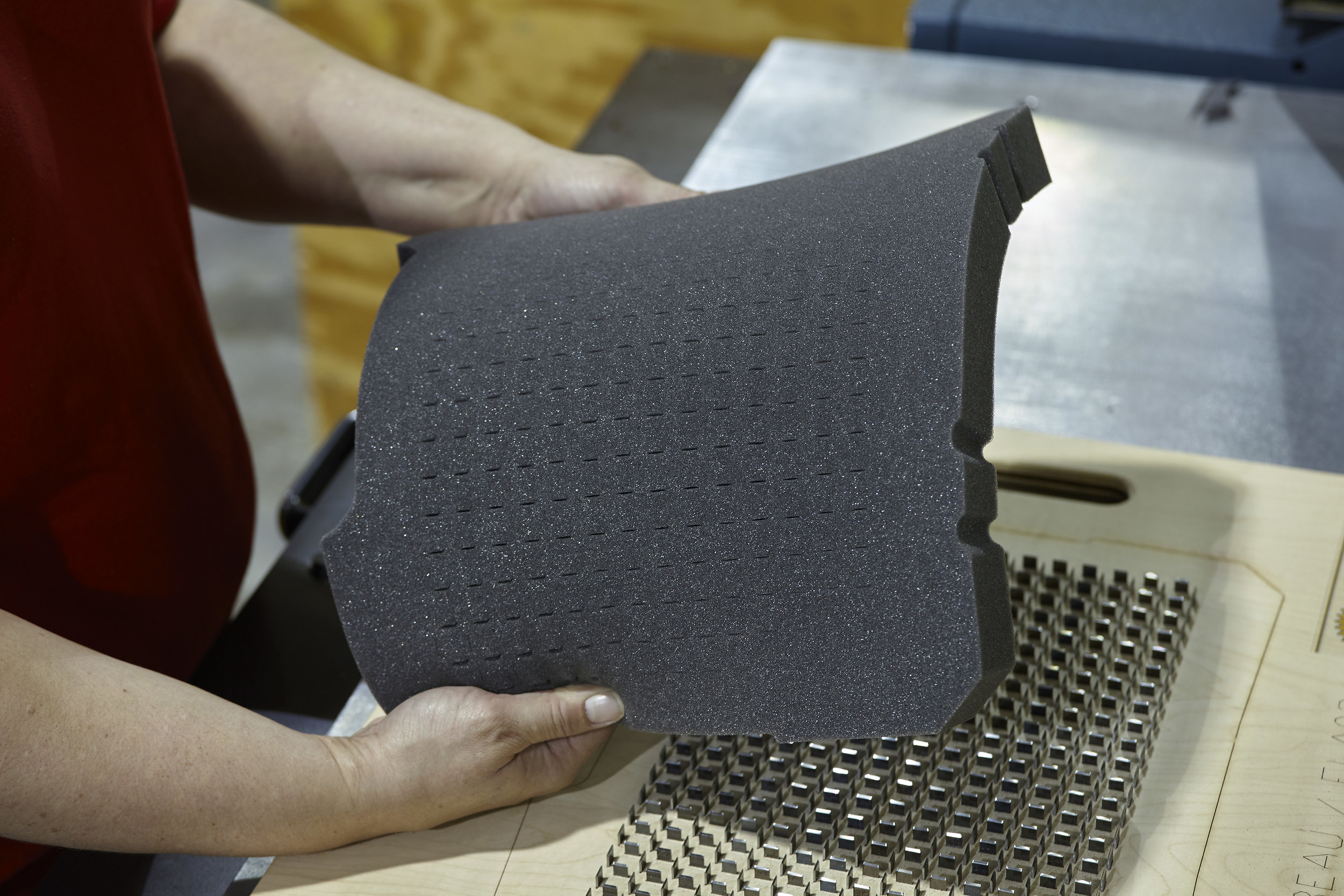

FLASH CUTTING

Cutting with extreme precision, the Foamcraft Flash Cutting capabilities meet the most strenuous tolerances, especially with technical foams. Serving as a "dieless die cutter," this machine is equipped with a blade that can telescope in and out of the material, providing the capability of cutting shapes out of the middle of foam part, without the need of tooling costs.